Week 15: This is why we don't have public 3D printers.

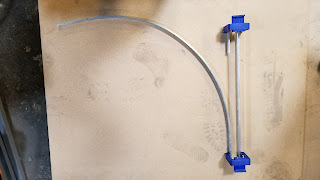

I have not spent too much time working on our group project this week. At home, I have continued to produce 3D printed parts. At Superway I have been asked to get the shops 3D printers up and running. One of the printers has not been operational since I entered Superway last semester. Since I have assembled two 3D printer kits I have a pretty good understanding of their functionality. To further add to this, I have spent quite a bit of time in Marlin (3D printer firmware) and I am very comfortable editing the source code for different printers. Most of my time at Superway this week has been dedicated to getting this finished. Although this means I am not working on the project it is a much needed break. I have spent all of the last weekend working. Standing during all of my shifts has taken a toll on me and spending some time at Superway sitting down is helping me recover. Thankfully, Angelo has taken the lead with finishing up the curved rail sections. Thursday of this week our team m